Dual-skinned polyamide/poly(vinylidene fluoride)/cellulose acetate membranes with embedded woven

H. Duong, S. P. Nunes, T.-S. Chung

Journal of Membrane Science, 520, 840-849,(2016)

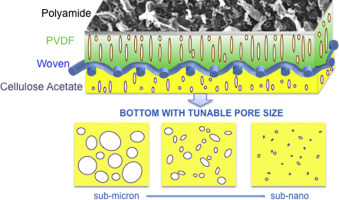

We propose multilayer membranes including (i) a thin selective polyamide (PA) layer prepared via interfacial polymerization, (ii) a poly (vinylidene fluoride) (PVDF) asymmetric porous support with high adhesion to the PA layer and high mechanical strength, (iii) a strong woven fabric, and (iv) fouling resistant porous cellulose acetate (CA) layer. The PA layer rejects solutes of the draw solution. The PVDF/woven fabric/CA (PVDF/CA) integrated layer performs as a mechanical support with unique properties for forward osmosis (FO) applications. It consists of a modified PVDF top layer suitable for the deposition of a PA layer and a highly hydrophilic bottom layer (CA) with a tunable pore size to minimize foulant deposition and intrusion onto and into the support. The experimental results using bovine serum albumin (BSA) as a model foulant show that the presence of the CA layer at the bottom of the FO membrane (PA/PVDF/CA) reduces 75% fouling propensity compared to the simple FO membrane made of PVDF, woven fabric and PA (PA/PVDF). Fouling tests with 2000 ppm oily feed faced the bottom of the FO membranes further indicate the superiority of the PA/PVDF/CA membrane compared to the PA/PVDF membrane. Moreover, the bottom CA layer can be adjusted with a flexible range of pore size, varied from sub-micron to sub-nanometer depending on the feed composition. The newly developed multilayer FO membrane has comparable performance to the state-of-the-art membrane with added tailored fouling resistance for specific wastewater feeds.