Hollow fiber membrane lumen modified by polyzwitterionic grafting

N. L. Le, M. Quilitzsch, H. Cheng, P. Hong, M. Ulbricht, S. P. Nunes, T.-S. Chung

Journal of Membrane Science, 522, 1-11, (2017)

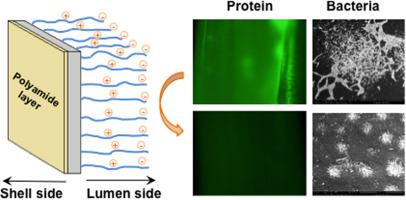

In this study, we demonstrate an effective way to modify the lumen of polyetherimide hollow fibers by grafting zwitterionic poly(sulfobetaine) to increase the membrane resistance to fouling. Surface-selective grafting of the protective hydrogel layers has been achieved in a facile two-step process. The first step is the adsorption of a macromolecular redox co-initiator on the lumen-side surface of the membrane, which in the second step, after flushing the lumen of the membrane with a solution comprising monomers and a complementary redox initiator, triggers the in situ cross-linking copolymerization at room temperature. The success of grafting reaction has been verified by the surface elemental analyses using X-ray photoelectron spectroscopy (XPS) and the surface charge evaluation using zeta potential measurements. The hydrophilicity of the grafted porous substrate is improved as indicated by the change of contact angle value from 44° to 30°, due to the hydration layer on the surface produced by the zwitterionic poly(sulfobetaine). Compared to the pristine polyetherimide (PEI) substrate, the poly(sulfobetaine) grafted substrates exhibit high fouling resistance against bovine serum albumin (BSA) adsorption, E. coli attachment and cell growth on the surface. Fouling minimization in the lumen is important for the use of hollow fibers in different processes. For instance, it is needed to preserve power density of pressure-retarded osmosis (PRO). In high-pressure PRO tests, a control membrane based on PEI with an external polyamide selective layer was seriously fouled by BSA, leading to a high water flux drop of 37%. In comparison, the analogous membrane, whose lumen was modified with poly(sulfobetaine), not only had a less water flux decline but also had better flux recovery, up to 87% after cleaning and hydraulic pressure impulsion. Clearly, grafting PRO hollow fiber membranes with zwitterionic polymeric hydrogels as a protective layer potentially sustains PRO performance for power generation.